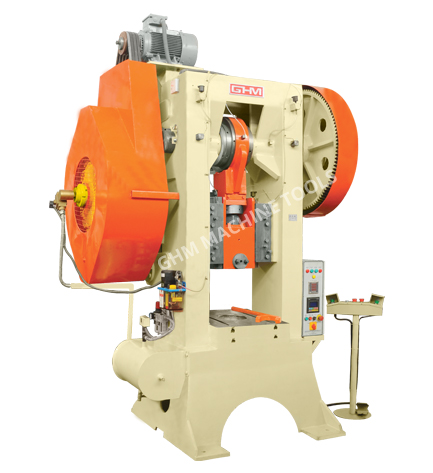

PNEUMATIC POWER PRESS

Pneumatic Power Press :-

Our Power presses cover the whole range of pressing and forming operations, and thus the customer is able to select the machine best suited to his requirements. The suitable press can be ascertained from a consideration of the purpose, the size of the production products, the material to be used and the required output. These presses are used for blanking, cutting, piercing, trimming, drawing, reducing, stamping, punching & bending. Power Presses what we are manufacture is of steel fabricated frame, using best raw materials that are tested for long life, efficiency and reliability. We also do stress relieving to all fabricated frames and follows standard practice of seasoning casting. Power press is equipped with an electro pneumatically operated plate friction clutch and brake combination. The pneumatic clutch has proved to be the most durable and, even when subjected to multi-shift operation. The clutch and brake permit the instantaneous stopping of ram at any point during the down-stroke.We also manufacture the customized Power presses in order to meet exact requirement of our customers from 10 ton to 1000 tons cap.

Specification :-

| Capacity in Tons | PP-30 | PP-50 | PP-75 | PP-100 | PP-150 | PP-200 | PP-250 | PP-300 |

| Bed Size in mm | 435x460 | 460x500 | 525x600 | 575x625 | 650x690 | 800x850 | 850x900 | 925x950 |

| Dist. Bed to Ram | 300 | 340 | 375 | 400 | 450 | 500 | 550 | 600 |

| Punch Bore | 32 | 40 | 45 | 50 | 55 | 63 | 65 | 70 |

| Stroke Length | 80 | 100 | 110 | 125 | 125 | 150 | 150 | 175 |

| Ram Adjustment | 25 | 35 | 35 | 35 | 50 | 50 | 50 | 50 |

| Shut Height | 185 | 210 | 250 | 275 | 300 | 300 | 350 | 400 |

| Stroke Per Minute | 60 | 60 | 50 | 45 | 40 | 35 | 35 | 35 |

| Bore in Table | 120 | 150 | 175 | 200 | 225 | 250 | 250 | 300 |

| Power Required | 3HP | 5HP | 7.5HP | 10HP | 15HP | 20HP | 25HP | 30HP |

| RPM | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 |

| Pulley Size | 150 | 150 | 150 | 150 | 175 | 200 | 200 | 225 |

| Air pressure for pneumatic clutch(Kgs/Cm2) | 5.5 to 6 | 5.5 to 6 | 5.5 to 6 | 5.5 to 6 | 5.5 to 6 | 5.5 to 6 | 5.5 to 6 | 5.5 to 6 |

In view of continuously development, we reserve the right to modify the design and or dimensions without notice.

Standard Accessories :-

- Pneumatic clutch

- Motor pulley

- Slide adjustable Spanner

- Fly Wheel guard

- Gear guard

- V-Belts

- Air filter

- Control panel

- Two hand push button control station

- Lubrication pump for all moving parts

- Knock out system

- Bronze metal bushes

Optional Accessories :-

- Motorised Lubrication Pump

- Die Cushion

- Anti vibration mounts

- Hydraulic overload safety device

- Pneumatic feeder

- Anti repeat Safety Device

- Electric motor

- Tie Rods

- Foundation bolts

- Special Electric controls

- Hand safety sensors

- PLC controlled system

- Electronic stroke counter

Facebook

Facebook Youtube

Youtube Google+

Google+ Twitter

Twitter Instagram

Instagram