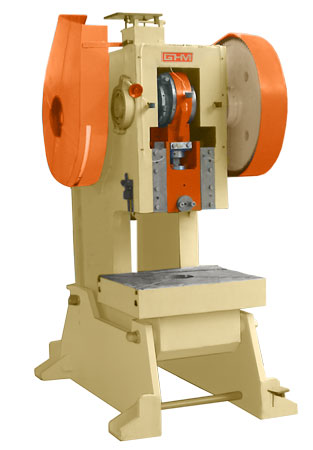

POWER PRESS C-Frame

POWER PRESS C-Frame :-

Our Power presses covers the whole range of pressing and forming operations. The press frame is made in one single piece weld body and is shaped like a 'C'. These presses are mostly employed for blanking, piercing, stamping, bending trimming and clinching operations. Power Presses what we are manufacture is of steel fabricated frame, using best raw materials that are tested for long life, efficiency and reliability. We also do stress relieving to all fabricated frames and follows standard practice of seasoning casting. These presses are provided with pedal operated rolling key clutch. We also manufacture the customized Power presses in order to meet exact requirement of our customers from 10 ton to 1000 tons cap.

Specification :-

| Capacity in Tons | PP-10 | PP-20 | PP-30 | PP-50 | PP-75 | PP-100 | PP-150 | PP-200 | PP-250 |

| Bed Size in mm | 350X425 | 375X500 | 450X600 | 500X700 | 550X800 | 600X900 | 720X1000 | 800X1100 | 850x1200 |

| Dist. Bed to Ram | 250 | 275 | 315 | 340 | 400 | 455 | 550 | 600 | 625 |

| Punch Bore size | 25 | 28 | 32 | 35 | 40 | 50 | 55 | 63 | 65 |

| Stroke Length | 50 | 63 | 83 | 95 | 105 | 125 | 125 | 140 | 150 |

| Ram Adjustment | 25 | 28 | 30 | 35 | 40 | 45 | 50 | 60 | 70 |

| Shut Height | 175 | 200 | 200 | 210 | 250 | 275 | 325 | 350 | 325 |

| Stroke Per Minute | 70 | 65 | 60 | 55 | 45 | 45 | 35 | 35 | 30 |

| Bore in Bed | 100 | 110 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| Power Required | 2HP | 2HP | 3HP | 5HP | 7.5HP | 10HP | 15HP | 20HP | 25HP |

| RPM | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 |

| Pulley Size | 125 | 125 | 150 | 150 | 150 | 150 | 175 | 200 | 200 |

Standard Accessories :-

- Motor Pulley

- Slide Adjustable Spanner

- Fly Wheel Guard

- Gear Guard

- Clutch Key Spring

- Lubrication Pump For All Moving Parts

- Knock Out System

- Bronze metal bushes.

Optional Accessories :-

- Motorised Lubrication Pump

- Die Cushion

- Pneumatic Clutch

- Anti Vibration Pads

- Hydraulic Overload Safety Device

- Pneumatic Feeder

- Anti Repeat Safety Device

- Electric Motor

- V-belts

- Tie Rods

- Hand Safety Sensors

- PLC Controlled System

Frame:- The Power Press Frame is fracture-proof all welded single piece construction made from fine tested steel with suitable cross ribbings. The steel constructed frame is stress relieved for having long life, high efficiency, utility and reliability.The advantages of steel construction :-

a) Higher modulus of elasticity

b) Higher strength

c) Due to a) and b), Smaller cross-sections, hence rigid frame

d) Absorb the heavy work load

Clutch :- The clutch is of rolling key type. The clutch is rigid and well supported. The clutch is giving continuous strokes for mass production and have long operating times.

Crank Shaft :- Crank shaft is made from special alloy steel and is having large bearing surfaces for smooth running fitted in bronze bushes ,finished to proper tolerances are provided for long life.

Gears :- The gears produced by our production units are able to fulfil all the standards. We use the best quality of raw materials for these gears. The team which is accountable for introspecting the quality standard of the manufactured gears, is comprised of experts having pool of knowledge in this respective fields.

Flywheel :- Flywheel is made from high grade cast iron. The Fly wheel are characterized by the fact that the fly wheel connected to accelerated at the start of working stroke. The fly wheel provides a predetermined amount of energy to the job and used for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running.

Lubrication :- The Purpose of the lubrication is to provide a film to ease the movement of the material over the tool and to reduce wear and tear on the latter. The lubricant is often required to cool the tool in addition. The lubricant is applied by hand pump or Motorised pump.

Table & Ram :- Table and Ram are made of high grade heavy duty cast iron & properly seasoned. They are perfectly aligned, to each other to obtain high accuracy & precision press operation.

Facebook

Facebook Youtube

Youtube Google+

Google+ Twitter

Twitter Instagram

Instagram